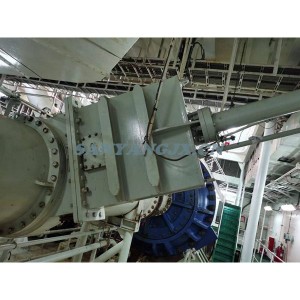

Dredge Gate Valve

Sanyang Heavy Machinery dredge gate valve is a component of a Cutter Suction Dredge or a Trailing Suction Hopper Dredger that is used control the flow of water and sand in the suction and discharge pipes of one of these types of dredgers.

Sanyang Heavy Machinery supplies extra wear-resistant dredge gate valves in various diameters with a special sealing and flushing system, suitable for the various pressures that can occur during the suction and discharge processes. We can offer regulating, shore and gate.valves for dredge pipes in a standard range from DN 400 up to DN 1200 mm, suitable for pressure up to 25 bar. All valves can be supplied with BV approval. It speaks for itself that we support you in selecting the right valve for your requirements.

Dredge Gate Valve – FEATURES

Designed in a way that there are no fasteners inside the body

Made of corrosion resistant and hard steel

The dredge valve body is stiffened with T-bars

Steel reinforced rubber seals are used to seal the pipe when the gate is down

Seals can be used on both sides and turned in opposite direction when worn out

All connections outside the body are bolts and nuts

Two flushing pipes are provided in the lower body

Made of fabricated high tensile steel and cast steel

Operated by hydraulic cylinder, located on the top of the dredge valve

The body is provided with inspection holes on both sides

The rubber seals are hardened where necessary to increase the life time of the seals

Fabricated body made from high tensile steel

Hoisting lugs provided on top of the body

Dredge Gate Valve – OPTIONS

Additional mechanical position indicator on the top of the dredge valve

Proximity sensors attached to the hydraulic cylinder

Dredge Gate Valve – More Photos

Sanyang Heavy Machinery offers you the one-stop service from design to after-sale service as a whole process of our business.

Product Range:

Dredging components and other customized products.

Customer Range:

Shipyards, Shipowners, Ship Managers, Engineering Companies, Constructors, Trading Companies, Wholesalers,etc.

Design Ability:

We have a very experienced, creative, and cooperative team, which can design the whole propulsion system according to different vessels and requirements.

Material Preparation:

Our purchasing dept. will choose the material from many aspects, such as cost, quality, machining, environment protection, etc.

Machining & Test:

We have advanced processing equipment with responsible crews. Our factory also have strict quality control process and test skills.

After-sale Service:

You will get the after-sale service all over the world. Convenient, Fast, High Efficiency, World-wide, etc.

Best service will be enjoyed by cooperating with us.

Packaging:

1. Wooden Case;

2. Iron Frame;

For different shipping methods and destinations, we will suggest different packaging.

If you have any requirement for the packaging, please let me know during enquiry.

Shipping:

We offer our clients one-stop service.The shipping tool can be by sea, by air or by train.

It depends on the destination of our products.

And we will suggest you the min. cost and min. damage of the products.