What is dredging equipment?

Dredging equipment refers to specialized machinery used in dredging projects to remove silt, sediment, deposits, or obstacles from the bottom of water bodies. This type of equipment is commonly used in river dredging, port dredging, waterway dredging, reservoir dredging, and other water conservancy projects. Its core function is to restore or improve the navigation capacity, flood control capacity, and ecological environment quality of waterways. Simply put, dredging equipment is a crucial foundation for ensuring the "smooth, safe, and sustainable operation" of waterways.

1. The Important Role of Dredging Equipment in Engineering Construction

Dredging equipment plays an irreplaceable role in various water conservancy and infrastructure construction projects:

- Improving waterway traffic capacity: Dredging equipment removes silt from the bottom of river channels or ports, ensuring safe navigation for ships.

- Enhancing flood control and drainage capacity: River dredging can effectively expand the flood discharge cross-section and reduce the risk of flooding.

- Ensuring the safe operation of water conservancy projects: Long-term siltation in reservoirs and lakes can affect water storage and management; dredging equipment can restore their designed functions.

- Promoting Ecological Restoration and Environmental Governance: Modern environmentally friendly dredging equipment reduces secondary pollution while removing silt, contributing to aquatic ecological restoration.

2. What are the common types of dredging equipment?

Dredging equipment can be divided into several types according to different operating methods and project requirements:

Cutter Suction Dredging Equipment

Cutter suction dredging equipment cuts through the riverbed or bottom silt with a cutter head and transports it through pipelines. It is one of the most widely used dredging equipment currently available and is suitable for large-scale river dredging projects.

Bucket Wheel Dredging Equipment

Bucket wheel dredging equipment boasts strong cutting capabilities, suitable for hard soil layers or highly compacted silt environments, and is commonly used in large-scale water conservancy dredging projects.

Grab Bucket Dredging Equipment

This type of dredging equipment offers flexible operation and is suitable for precise dredging operations in localized areas such as ports and docks.

Environmentally Friendly Dredging Equipment

Environmentally friendly dredging equipment emphasizes mud-water separation and reduces pollution diffusion during construction, and is widely used in ecological dredging projects such as urban river and lake management.

3. Core Technical Features of Dredging Equipment

With technological advancements, modern dredging equipment is continuously upgrading in terms of performance and intelligence:

- High-efficiency power systems improve dredging efficiency and reduce unit project costs.

- Wear-resistant cutting structures extend equipment lifespan.

- Intelligent control systems enable precise positioning and automated operation.

- Modular design facilitates transportation, installation, and maintenance.

- Energy-saving and environmentally friendly design aligns with the trend of green dredging development.

These technological advancements enable dredging equipment to maintain efficient and stable operation even under complex working conditions.

What equipment is used in dredging operations?

With the continuous advancement of water conservancy infrastructure construction, waterway improvement, and ecological restoration projects, dredging has become a crucial means of ensuring smooth river flow, port operation, and water environment improvement. In actual dredging projects, dredging efficiency and construction quality largely depend on the selection and configuration of equipment.

I. Basic Equipment Requirements for Dredging Operations

Dredging operations typically face complex underwater environments, long construction cycles, and significant variations in working conditions. Therefore, high requirements are placed on dredging equipment, including:

- Strong excavation or cutting capabilities

- Adaptability to different soil types and hydrological conditions

- Stable operation and strong continuous operation capability

- Meeting environmentally friendly dredging and green construction requirements

Based on these, dredging projects will configure different types of dredging equipment according to project scale and construction objectives.

II. Major Dredging Equipment Commonly Used in Dredging Operations

1. Cutter Suction Dredging Equipment

Cutter suction dredging equipment is one of the most widely used equipment in current dredging operations. This equipment cuts through the silt or soil at the bottom of the water using a cutter head, and then uses a suction pump to transport the slurry to the designated area.

Key Features:

- High dredging efficiency and strong continuous operation capability

- Suitable for river dredging, waterway dredging, and reservoir dredging

- Capable of long-distance pipeline transportation

2. Bucket Wheel Dredging Equipment

Bucket wheel dredging equipment relies on a high-speed rotating bucket wheel to cut and collect sediment from the bottom of the water. It is suitable for dredging conditions with hard soil or high compaction.

Main Application Scenarios:

- Large-scale water conservancy dredging projects

- Hard riverbeds or areas with high-density siltation

- Projects requiring high dredging precision

3. Grab Bucket Dredging Equipment

Grab bucket dredging equipment is usually operated by a crane vessel or floating crane carrying a grab bucket. It features flexible operation and precise positioning.

Main Advantages:

- Suitable for localized dredging operations in ports, docks, etc.

- Easy to remove obstacles and construction debris

- Flexible construction organization

4. Environmentally Friendly Dredging Equipment

With the increasing demand for ecological governance, environmentally friendly dredging equipment is being used more and more widely in dredging operations. This type of equipment focuses on reducing sediment diffusion and water disturbance during construction.

Key Features:

- Effectively reduces secondary pollution

- Suitable for dredging urban rivers and lakes

- Meets green dredging and ecological restoration requirements

III. Auxiliary Equipment Configuration in Dredging Operations

In addition to the core dredging equipment, a complete dredging operation requires the coordinated operation of various auxiliary equipment:

- Slurry transport pipeline system: Used to transport dredged material to designated storage or treatment areas

- Positioning system and measuring equipment: Ensures dredging accuracy and construction quality

- Power and generator equipment: Provides a stable energy source for the dredging equipment

- Transport vessels and mud barges: Used for the transfer and treatment of dredged material

These auxiliary equipment play a crucial role in improving the overall efficiency of dredging operations.

IV. How to Select Dredging Equipment Based on Project Needs?

In actual dredging projects, equipment selection needs to comprehensively consider the following factors:

- Scale and depth of the dredged water area

- Substrate type (silt, sand, or hard soil)

- Project cycle and construction intensity

- Environmental requirements and construction standards

Scientific and rational configuration of dredging equipment is key to ensuring the safe and efficient completion of dredging operations.

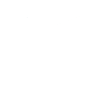

What engineering needs drive the development of dredging equipment?

I. Navigation Needs of Waterways and Ports Drive the Development of Dredging Equipment

In port construction and waterway maintenance projects, waterway siltation is a long-standing problem. Sediment deposition directly affects waterway depth, restricting the safe navigation of large vessels. To meet the demands of port expansion, channel deepening, and routine maintenance, the engineering field urgently needs dredging equipment with strong operational capabilities and high continuous construction efficiency.

It is against this backdrop that high-efficiency dredging equipment, such as cutter suction dredgers and bucket wheel dredgers, has been continuously developed and optimized to adapt to large-scale, long-cycle channel dredging projects.

II. Practical Needs of Flood Control, Drainage, and River Regulation

Long-term siltation in river channels leads to a decrease in flood discharge capacity, increasing the risk of flooding. In the process of promoting river regulation and flood control projects, various regions have placed higher demands on dredging equipment:

- The ability to quickly remove large amounts of silt

- Adaptability to different river widths, water depths, and soil conditions

- Ensuring construction safety and project quality

III. Reservoir and Lake Dredging and Water Conservancy Project Operation Needs

Reservoirs and lakes are prone to siltation during long-term operation, affecting their water storage capacity and dispatching functions. Traditional manual dredging methods are inefficient and costly, making them unsuitable for modern water conservancy projects.

Therefore, dredging equipment development fully considers the characteristics of reservoir and lake operating environments, emphasizing:

- Long-distance transport capability

- Continuous operation performance

- Controllability of water disturbance

IV. Engineering Requirements for Complex Working Conditions and Diverse Soil Types

Different dredging projects face significant differences in soil types, including silt, sand, clay, and even hard sedimentary layers. The diversification of engineering requirements has driven continuous upgrades in the structural design and functional configuration of dredging equipment.

For example:

- For soft silt, developing efficient suction systems

- For hard soil layers, strengthening cutting and wear-resistant structures

- For complex hydrological conditions, improving equipment stability

V. Increasing Demand for Environmentally Friendly Dredging and Ecological Restoration Projects

With increasingly stringent environmental protection requirements, dredging projects are no longer solely focused on construction efficiency, but also on the impact of the construction process on the aquatic environment. Engineering practice urgently requires environmentally friendly dredging equipment with low disturbance and low dispersion.

Therefore, modern dredging equipment development places greater emphasis on:

- Reducing sediment dispersion and secondary pollution

- Lowering noise and energy consumption

- Meeting ecological dredging and green construction standards

VI. Practical Needs for Engineering Efficiency and Cost Control

In large-scale dredging projects, the construction period and overall cost directly impact project profitability. Project owners aim to achieve the following through high-performance dredging equipment:

- Increase dredging volume per unit time

- Reduce equipment failures and downtime

- Lower labor and maintenance costs

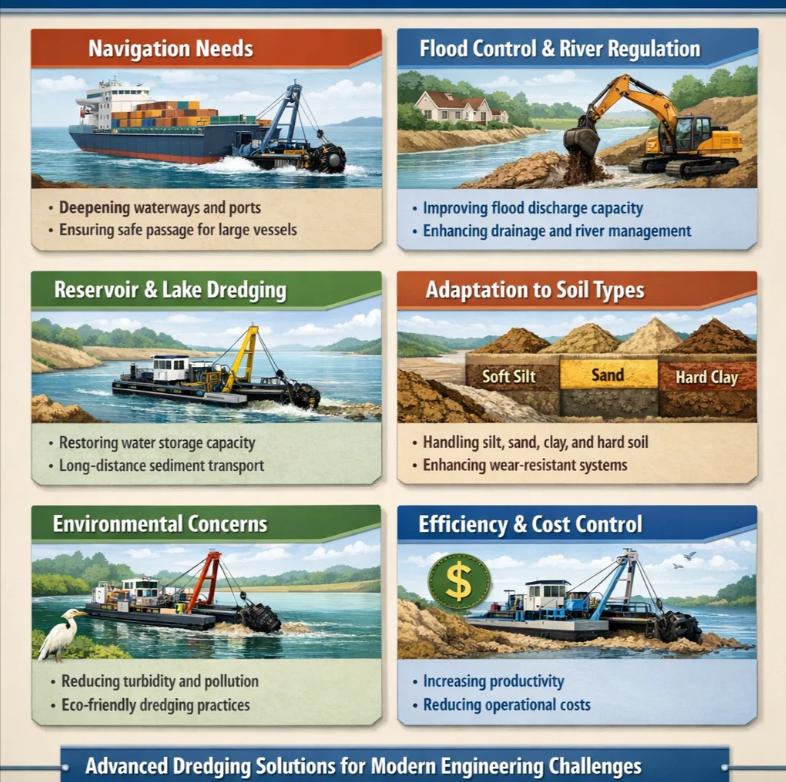

Can dredging equipment remain efficient under conditions of high sediment and high hardness?

In river dredging, port and waterway improvement, and large-scale water conservancy projects, high sediment content and high-hardness bottom sediments have always been considered among the most challenging construction conditions. In such environments, the stability of dredging efficiency and the reliability of equipment directly affect project progress and construction costs.

I. What challenges do high sediment and high hardness conditions pose to dredging operations?

In actual dredging projects, high sediment and high hardness conditions typically exhibit the following characteristics:

- High sediment concentration, resulting in high transport resistance.

- Complex soil structure, leading to high cutting difficulty.

- Equipment wear rate is significantly accelerated.

- Higher requirements for continuous operation stability.

II. How does dredging equipment cope with high sediment conditions?

For high sediment environments, modern dredging equipment development focuses on enhancing the transport and power system capabilities:

- Using high-flow, high-lift suction pumps to ensure stable transport of high-concentration slurry.

- Optimizing pipeline design to reduce the risk of sediment deposition and blockage.

- Improving the matching degree of the power system to achieve continuous high-load operation.

III. Is the cutting capability of dredging equipment sufficient for high-hardness substrates?

High-hardness conditions are often accompanied by compacted clay, gravel layers, and even localized hard sediment layers, posing a severe challenge to the cutting system of dredging equipment. To address this, dredging equipment has undergone continuous structural design upgrades:

- Equipped with high-strength cutterheads or bucket wheel cutting devices

- Key components utilize wear-resistant alloy materials

- Optimized cutting angles and rotational speeds to improve soil breaking efficiency

IV. Wear resistance and reliability are key guarantees for efficient operation

In high-silt, high-hardness conditions, the wear resistance of the equipment directly determines its continuous operating capability. Current mainstream dredging equipment is designed with long-term high-wear environment requirements in mind:

- Modular design of vulnerable components for easy replacement and maintenance

- Strengthened wear-resistant treatment of key components to extend service life

- Increased overall structural strength to reduce failure rate

V. Practical Engineering Applications Verify the High Efficiency of Dredging Equipment

From numerous river and waterway dredging projects, it is evident that properly selected and scientifically configured dredging equipment can still achieve the following even under conditions of high sediment and high hardness:

- Stable and controllable dredging efficiency

- Significantly extended continuous operation time

- Significantly shortened construction cycle

How to Ensure Construction Safety with Dredging Equipment?

In river dredging, port and waterway construction, and water conservancy dredging projects, the construction environment is complex and underwater operations are highly risky. Safety is always a core concern in project management. As key construction equipment in dredging projects, dredging equipment plays a crucial role in ensuring construction safety.

I. Complex Construction Environments Place Higher Demands on Dredging Safety

Dredging operations typically need to be carried out in environments with large variations in water depth, complex currents, and unstable bottom sediments. They may also face challenges such as severe weather and prolonged continuous construction. These factors place higher demands on the safety performance of dredging equipment:

- The equipment must possess excellent stability and resilience.

- It must be able to maintain a reliable state under high-load operation.

- It must have comprehensive safety protection and emergency response mechanisms.

II. Structural Design Provides a Fundamental Guarantee for Construction Safety

Modern dredging equipment fully considers the safety requirements of water operations during the structural design phase:

- Stable hull structure with strong anti-capsulation capability

- High-strength materials are used in key load-bearing components

- Rational equipment layout reduces operational risks

III. Multiple Safety Control Systems Reduce Operational Risks

To further enhance construction safety, dredging equipment is generally equipped with multiple safety control systems:

- Automatic monitoring system to monitor equipment operating status in real time

- Overload protection device to prevent equipment from operating under overload conditions

- Emergency shutdown system for rapid response in emergencies

IV. Safety Protection of Electrical and Power Systems

In dredging operations, the safety of the power and electrical systems directly affects the stability of the entire machine's operation. Modern dredging equipment emphasizes the following in its design:

- Waterproofing, moisture-proofing, and insulation protection for the electrical system

- Real-time monitoring of temperature and pressure in the power system

- Fault warning and alarm mechanisms for key components

V. Ergonomics and Operational Safety Design

Dredging equipment not only focuses on the safety of the equipment itself but also highly values the operational safety of operators:

- Clear operating interface, reducing the risk of misoperation

- Safety interlocks are set up for key operating procedures

- Providing a good operating view and working environment

- Optimized ergonomic design effectively improves the overall safety level of dredging operations

VI. Maintenance Management and Safe Operation Assurance

Construction safety depends not only on equipment design but also on scientific maintenance management. During long-term operation, dredging equipment is ensured safety through the following methods:

- Regularly inspecting the operating status of key components.

- Replacing vulnerable parts promptly to avoid operation with malfunctions.

- Providing supporting technical training to improve operators' safety awareness.

A comprehensive maintenance and management system is a crucial guarantee for the safe operation of dredging equipment.

English

English 中文简体

中文简体