What is a cold bending machine?

In the modern shipbuilding and metal processing industry, cold bending machines, as a core forming equipment, are gradually replacing traditional hot forming methods, becoming crucial for improving shipbuilding quality and efficiency.

1. Basic Definition and Applications of Cold Bending Machines

A cold bending machine is a high-precision device that uses cold forming technology to process metal sheets (such as marine steel plates) into various complex geometric surfaces at room temperature.

It is the main equipment for forming curved surfaces of ship hulls, capable of handling marine steel plates with thicknesses between 6 and 50 millimeters. Whether it's a delicate small yacht or a magnificent giant oil tanker, the cold bending machine can precisely bend its thick steel plates into the required curvature, meeting diverse application scenarios.

2. Working Principle of Cold Bending Machines: From Elasticity to Plasticity

The core operating logic of cold bending machines lies in the precise control of the physical properties of metal materials. Its typical structural features are as follows:

Roller Arrangement:

Typically, a symmetrical arrangement of three or four rollers is used.

Forming Process:

The equipment applies progressive pressure to the steel plate through the rollers. In the initial stage of processing, the metal first undergoes elastic deformation; as the pressure increases, the metal enters a state of plastic deformation, thus permanently changing its shape.

Multi-Axis Linkage:

For complex hyperboloid sheets (three-dimensional curved surfaces), advanced cold bending machines can achieve multi-axis linkage control, ensuring that the bending curvature in every dimension is perfectly aligned.

3. Intelligent Control and Precision Monitoring

Modern cold bending machines are no longer simple mechanical presses, but precision instruments integrating CNC numerical control technology:

Servo Drive and PLC Control:

The equipment is driven by high-performance servo motors, and the pressure and feed speed of each roller are precisely adjusted through a PLC (Programmable Logic Controller) system.

Real-time Feedback and Springback Compensation:

Metal will produce a certain amount of "springback" after bending. The real-time feedback system of a cold bending machine monitors sheet metal deformation and automatically calculates and compensates for springback, ensuring the final dimensions perfectly match the design model.

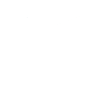

What is the difference between hot bending and cold bending?

In metal processing and shipbuilding, bending rigid steel sheets into ideal shapes is a core technology. Hot bending and cold bending are two distinctly different processes.

1. Difference in Process Principles

Hot bending:

Utilizes high-temperature heating (usually to a red-hot state) to soften the metal, reducing its yield strength, thus achieving plastic deformation under relatively small external forces.

Cold bending:

At room temperature, uses equipment such as a cold bending machine to force deformation through mechanical pressure. Taking an advanced CNC cold bending machine as an example, it applies progressive pressure to the steel sheet using three or four symmetrically arranged rollers, causing it to transition from elastic deformation to plastic deformation.

2. Forming Accuracy and Surface Quality

In industries with extremely high precision requirements (such as aerospace and precision shipbuilding), cold bending machines exhibit significant technological advantages:

Linear Accuracy:

Due to the uncertainty of thermal expansion and contraction during hot bending, shrinkage deformation often occurs after cooling. In contrast, the linear accuracy of cold bending can be improved by three times. The forming accuracy of modern CNC cold bending machines can reach ±0.5 mm/m.

Surface Quality:

Hot working easily produces oxide scale or fire damage on the metal surface. Cold bending can achieve a steel plate surface quality of Sa2.5 grade, creating ideal surface conditions for subsequent automatic welding.

3. Physical Properties and Material Damage

This is one of the most fundamental differences between the two. Cold bending machines ensure that material properties are not affected by heat during processing.

Hot Bending:

High temperatures can alter the internal structure of steel and even cause certain alloying elements to fail, affecting the mechanical strength of the steel plate.

Cold Bending:

Operating at room temperature, it completely preserves the initial mechanical properties of raw materials such as marine steel plates. Through a real-time feedback system, the cold bending machine can automatically compensate for metal springback, ensuring that the final dimensions precisely match the design drawings.

4. Processing Capabilities and Application Scenarios

While the cold bending machine excels in precision, both have their specific application areas:

Hot Bending:

Typically used for special parts with extremely large thicknesses, very small radii, or extremely complex shapes, as high temperatures significantly reduce deformation resistance.

Cold Bending:

Currently the mainstay for ship hull surface forming. It can handle marine steel plates with thicknesses ranging from 6 to 50 mm. For special hyperboloidal plates, high-performance cold bending machines can achieve multi-axis linkage control, easily handling the challenges of three-dimensional curved surfaces.

What are the three types of bending?

In the fields of metal processing, shipbuilding, and pressure vessel manufacturing, bending is the most basic and crucial means of changing the shape of materials. Based on differences in processing temperature, mechanical characteristics, and equipment operation, the industry generally classifies bending into three main types.

1. Cold Bending (Room Temperature Forming)

Cold bending refers to a bending process performed below the recrystallization temperature of the metal material (usually room temperature). It is currently the most widely used and highest-precision technology in the shipbuilding industry.

Core Equipment:

Primarily uses a cold bending machine. This equipment employs a symmetrical arrangement of three or four rollers, driven by a servo motor, to apply progressive pressure to the sheet metal.

Technical Advantages:

Maintaining Material Properties: The material is unaffected by heat during processing, fully preserving the initial mechanical strength of the steel.

High Precision: With a CNC system (PLC), forming accuracy can reach ±0.5 mm/m, three times higher than traditional processes.

Surface Quality: Due to the absence of oxide scale, surface quality can reach Sa2.5 grade, providing ideal conditions for subsequent welding.

2. Hot Bending (High-Temperature Forming)

Hot bending is the bending of metal by heating it to above its recrystallization temperature (typically between 800°C and 1000°C).

Process Characteristics:

As the temperature increases, the yield strength of the metal decreases significantly, while its plasticity increases. This allows it to handle ultra-thick steel plates or achieve bending with extremely small radii of curvature.

Limitations:

Heat-Affected Zone: High temperatures can alter the internal metallographic structure of the metal, leading to performance fluctuations.

Difficulty in Precision Control: Shrinkage deformation during cooling is difficult to predict accurately.

Environmental Impact: High energy consumption and oxide scale formation, requiring extensive subsequent grinding processes.

3. Plastic Bending and Complex Forming (Multi-Axis Linkage Bending)

This type primarily refers to special forming methods for hyperboloidal sheets or complex three-dimensional surfaces. It is often an advanced version of cold bending.

Process Characteristics:

The equipment uses multi-axis linkage control to cause the sheet metal to bend not only longitudinally but also laterally or in other dimensions.

Real-time Monitoring:

This process relies on a real-time feedback system. Due to the elastic rebound of metal, the system must monitor deformation in real time and automatically compensate to ensure that the final dimensions perfectly match the design model.

Application Scenarios:

Widely used in the processing of high-precision ship hulls, spherical storage tanks, and streamlined exterior walls of modern buildings.

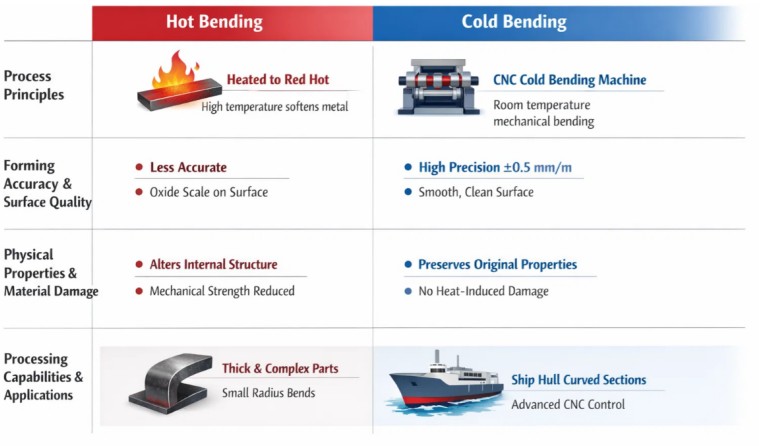

How to Cold Bending Metal?

In modern industrial manufacturing, cold bending metal has become a core technology for achieving high-precision forming. Unlike traditional hot working, cold bending can shape tough steel plates into complex geometric shapes without altering their physical properties.

1. Core Principles of Cold Bending

The core of cold bending metal lies in using mechanical force to push the material beyond its yield strength. This process is typically carried out at room temperature, applying pressure to the metal sheet (such as marine steel plates with a thickness of 6 to 50 mm) using the rollers of a cold bending machine.

From Elastic to Plastic:

The metal first undergoes elastic deformation, returning to its original shape after the external force is removed. As the pressure continues to increase, the metal enters a state of plastic deformation, thus obtaining a permanent bent shape.

Springback Compensation:

After bending, the metal will spring back to a certain extent due to the existence of the elastic modulus. Modern CNC cold bending machines, through a real-time feedback system, can automatically monitor deformation and perform springback compensation, ensuring accurate final dimensions.

2. Key Steps in Performing Cold Bending Metal

Step One: Parameter Setting and Pre-bending

Input the curvature parameters from the design drawings through the PLC control system. For thick plate processing, pre-bending at the ends is crucial to ensuring the continuity of the overall curvature, effectively reducing forming blind spots.

Step Two: Progressive Pressure Application

The cold bending machine employs a symmetrical arrangement of three or four rollers. Driven by a servo motor, the rollers slowly press down, feeding the sheet metal. This progressive pressure prevents internal cracking in the metal, preserving material properties from the effects of heat.

Step Three: Multi-Axis Linkage and 3D Forming

For complex hyperboloid sheets, the equipment activates a multi-axis linkage control mode. By precisely adjusting the relative position and tilt angle of each roller, the steel sheet is bent simultaneously in both the longitudinal and transverse directions, achieving a forming accuracy of ±0.5 mm/m.

3. Advantages of Cold Bending: Why Choose Cold Bending?

Compared to hot bending, cold-bending metal offers significant advantages in shipbuilding, bridge construction, and building steel structures:

High Precision Performance: Cold bending can improve line accuracy by three times, making it the primary solution for creating high-quality ship hull surfaces.

Superior Surface Quality: The processed surface is free of oxide scale, achieving a quality grade of Sa2.5, creating perfect conditions for subsequent automated welding processes.

Energy Saving and Environmental Protection: No high-energy-consuming heating equipment is required; the processing is clean and efficient.

4. Key Equipment: The Role of the CNC Cold Bending Machine

The core of achieving perfect cold bending lies in the performance of the equipment. A high-quality CNC cold bending machine integrates:

Servo Drive System: Provides smooth and powerful torque.

Intelligent Sensors: Monitors sheet thickness deviations and hardness changes in real time.

Automated Compensation Software: Ensures processing consistency from small yacht components to large tanker sheets.

Cold bending of metal is a precision process combining materials mechanics and CNC technology. By selecting a suitable cold bending machine and using scientific processing steps, companies can significantly improve the forming accuracy and surface quality of their products while ensuring material performance.

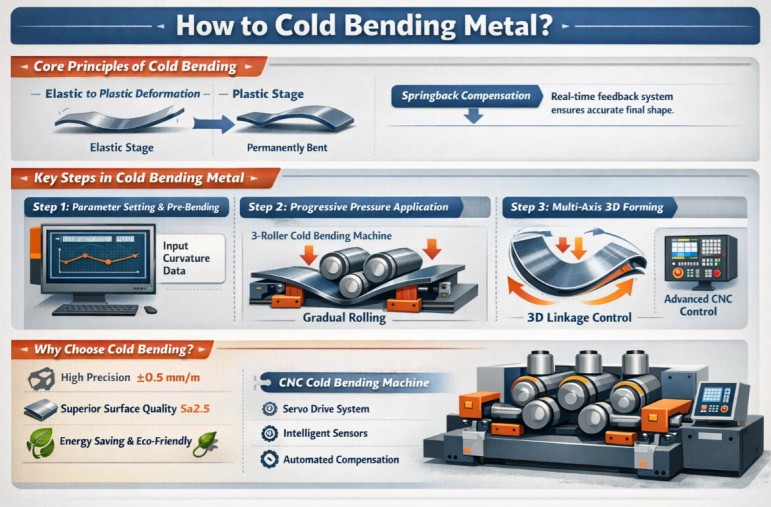

What is the process flow of cold bending?

In modern manufacturing, cold bending machines have become core equipment in shipbuilding, steel structure construction, and other fields. Compared to traditional processes, cold bending, with its high precision and protection of material properties, has become the preferred method for processing 6 to 50 mm thick marine steel plates.

1. Preparation Stage: Parameter Input and Material Inspection

The first step in cold bending begins with digitization. Operators first need to input the curvature parameters into the PLC control system of the CNC cold bending machine according to the design drawings.

Material Inspection:

Verifying the thickness, yield strength, and initial flatness of the steel plate.

Process Simulation:

The advanced CNC system simulates the bending process in advance, calculating the elastic deformation of the metal and the expected springback value, laying the foundation for precise processing.

2. Core Stage: Progressive Bending Forming

This is the core step of the cold bending process, mainly achieved through the physical extrusion of the cold bending machine.

Feeding and Positioning:

The steel plate is fed between the rollers of the equipment. This equipment typically uses a symmetrical arrangement of three or four rollers to ensure uniform stress.

Applying Pressure:

Driven by a servo motor, the working rollers move downwards, applying progressive pressure to the steel plate. The metal material gradually transitions from an elastic state to a plastic deformation state.

Multi-Axis Linkage Control:

For complex hyperboloid sheets, the equipment uses multi-axis linkage to precisely adjust the roller tilt angle and feed speed, allowing the steel plate to form the target curvature in three-dimensional space.

3. Real-Time Monitoring and Automatic Compensation:

During the bending process, a real-time feedback system monitors the deformation of the sheet throughout. Due to the natural springback characteristics of metal, the system automatically adjusts the pressure of each roller based on sensor data for springback compensation.

This intelligent adjustment ensures a final forming accuracy of ±0.5 mm/m, ensuring the part dimensions perfectly match the design.

4. Surface Treatment and Quality Inspection

A major advantage of cold bending is that the material is unaffected by heat, thus preventing oxide scale or thermal deformation.

Surface Quality:

Steel plates processed by a cold bending machine typically achieve a surface quality of Sa2.5 grade.

Precision Verification:

Curvature is checked using templates or laser scanners to ensure ideal conditions for subsequent automated welding.

Significant Advantages of Cold Bending Process:

High Linearity: Compared to traditional hot bending, cold bending can improve linearity accuracy by three times.

Maintaining Mechanical Properties: Because plastic deformation occurs at room temperature, the internal structure of the steel plate remains stable, and its strength is not reduced.

High Efficiency and Energy Saving: Eliminating the need for high-energy-consuming equipment such as heating furnaces significantly reduces production costs.

From digital input to multi-axis linkage forming and precise springback compensation, the cold bending machine's process embodies the intelligence and standardization of modern metal processing. This technology not only improves the manufacturing quality of everything from small yachts to large oil tankers but also promotes the green transformation of the heavy industry.

English

English 中文简体

中文简体